AI Applications in Pipeline Monitoring

Written : Dr.Nabil Sameh

1. Introduction

Pipeline systems are the backbone of oil and gas transportation, enabling the safe and efficient movement of hydrocarbons from production fields to processing facilities, refineries, and end users. Given their extensive length, harsh operating environments, and exposure to mechanical, chemical, and environmental stresses, pipelines are vulnerable to a wide range of integrity threats. These include corrosion, leaks, material degradation, ground movement, operational anomalies, and third-party interference.

Traditional pipeline monitoring methods rely heavily on periodic inspections, rule-based alarm systems, and manual data interpretation. While these approaches have supported pipeline operations for decades, they often suffer from delayed detection, limited predictive capability, and high operational costs. As pipeline networks expand and operate under increasingly complex conditions, the need for intelligent, adaptive, and real-time monitoring systems has become critical.

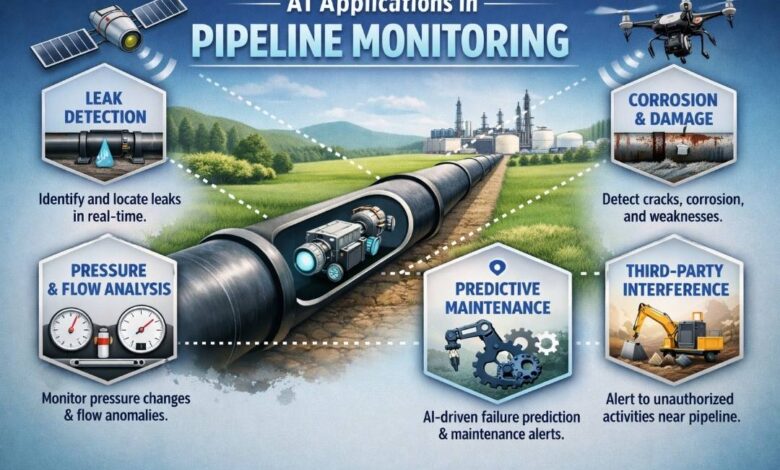

Artificial Intelligence (AI) has emerged as a transformative technology capable of addressing these challenges. By enabling machines to learn from data, recognize patterns, and make informed decisions, AI introduces a new paradigm for pipeline monitoring—one that is proactive rather than reactive. This article presents a comprehensive theoretical discussion of AI applications in pipeline monitoring, focusing on concepts, methodologies, and system-level integration without reference to specific case studies or regulatory frameworks.

2. Fundamentals of Pipeline Monitoring Systems

Pipeline monitoring refers to the continuous or periodic observation of pipeline conditions to ensure safe, reliable, and efficient operation. Traditional monitoring systems typically collect data from sensors measuring parameters such as pressure, flow rate, temperature, vibration, and acoustic signals. These data are transmitted to centralized control systems, where predefined thresholds and deterministic models are used to trigger alarms or corrective actions.

Although effective for basic operational control, conventional systems face several limitations. They often depend on static thresholds that fail to adapt to changing operating conditions. Noise in sensor data can lead to false alarms, while subtle anomalies may go undetected if they do not exceed preset limits. Furthermore, traditional systems struggle to correlate large volumes of heterogeneous data from multiple sources, limiting their ability to provide holistic insights into pipeline health.

AI-based monitoring systems differ fundamentally in their approach. Instead of relying solely on fixed rules, AI systems learn patterns from historical and real-time data. They can distinguish between normal operational variations and abnormal behaviors, even when such deviations are complex, nonlinear, or previously unseen. This shift from rule-based monitoring to data-driven intelligence forms the foundation of AI-enabled pipeline monitoring.

3. Role of Artificial Intelligence in Pipeline Monitoring

Artificial Intelligence encompasses a broad range of computational techniques designed to emulate aspects of human intelligence. In pipeline monitoring, AI serves as an analytical engine that transforms raw sensor data into actionable insights. Its primary strength lies in its ability to process massive datasets, identify hidden relationships, and continuously improve performance through learning.

Machine learning algorithms enable systems to recognize patterns associated with normal pipeline behavior and detect deviations that may indicate potential issues. Deep learning models extend this capability by analyzing highly complex data types such as acoustic emissions, vibration signals, and distributed sensing data. Unlike traditional algorithms, AI models can adapt to evolving pipeline conditions, aging infrastructure, and changing operational strategies.

AI also introduces predictive intelligence into pipeline monitoring. Instead of merely identifying existing problems, AI systems can forecast future degradation trends, estimate failure probabilities, and support proactive maintenance planning. This predictive capability represents a fundamental shift in how pipeline integrity is managed, moving from corrective and preventive approaches toward predictive and prescriptive strategies.

4. AI-Based Anomaly Detection in Pipelines

Anomaly detection is one of the most critical applications of AI in pipeline monitoring. Anomalies refer to deviations from normal operational behavior that may signal leaks, blockages, equipment malfunctions, or external interference. In complex pipeline systems, anomalies are not always obvious and may manifest as subtle changes across multiple parameters.

AI-based anomaly detection systems learn the normal operational signature of a pipeline under various conditions. By continuously comparing real-time data against learned patterns, these systems can identify abnormal behaviors even when they do not trigger traditional alarms. This capability is particularly valuable for detecting small leaks, gradual corrosion effects, or early-stage mechanical failures.

Unlike deterministic models, AI-based anomaly detection does not require explicit physical modeling of every possible failure scenario. Instead, it relies on statistical and computational learning to infer abnormality. This allows AI systems to detect novel or unforeseen events, enhancing the robustness of pipeline monitoring in complex and uncertain environments.

5. Predictive Pipeline Integrity and Failure Forecasting

One of the most powerful contributions of AI to pipeline monitoring is its ability to predict future integrity risks. Predictive monitoring involves analyzing historical and real-time data to estimate the likelihood of degradation, failure, or performance loss over time.

AI models can capture long-term trends related to corrosion progression, material fatigue, pressure cycling effects, and environmental influences. By learning how these factors interact, AI systems can forecast deterioration patterns and identify segments of the pipeline that are at higher risk. This enables operators to prioritize inspections, maintenance, and rehabilitation activities based on risk rather than fixed schedules.

Predictive AI systems also support decision-making by quantifying uncertainty. Instead of binary assessments, they provide probabilistic insights that help engineers evaluate trade-offs between safety, cost, and operational continuity. This intelligence-driven approach enhances both reliability and economic efficiency in pipeline operations.

6. AI Integration with Sensor Networks and Data Streams

Modern pipelines are increasingly instrumented with advanced sensor technologies, generating vast volumes of data. These data streams include pressure and flow measurements, acoustic signals, vibration data, and distributed sensing outputs. AI plays a central role in transforming this raw data into meaningful information.

AI algorithms are particularly effective at handling high-dimensional, noisy, and heterogeneous datasets. They can filter irrelevant noise, reconcile conflicting signals, and extract features that are not readily apparent through conventional analysis. This capability is essential for real-time monitoring, where rapid and accurate interpretation of data is required.

Furthermore, AI enables intelligent data fusion, combining information from multiple sensors and sources into a unified understanding of pipeline behavior. This holistic perspective improves situational awareness and supports more accurate diagnostics, especially in complex pipeline networks spanning diverse terrains and operating conditions.

7. Automation and Decision Support in Pipeline Monitoring

Beyond detection and prediction, AI enhances pipeline monitoring through automation and decision support. AI-driven systems can autonomously classify events, assess severity levels, and recommend appropriate responses. This reduces reliance on manual interpretation and minimizes human error, particularly in high-pressure or time-critical situations.

Decision support systems powered by AI provide engineers and operators with prioritized alerts, contextual insights, and scenario-based recommendations. Rather than overwhelming users with raw data or excessive alarms, AI systems present concise, relevant information that supports informed decision-making.

Over time, AI systems can learn from operator feedback and outcomes, continuously refining their recommendations. This adaptive learning capability ensures that monitoring systems evolve alongside operational practices and infrastructure changes, maintaining long-term effectiveness.

8. Challenges and Limitations of AI in Pipeline Monitoring

Despite its significant potential, the application of AI in pipeline monitoring is not without challenges. One key limitation is data quality. AI models are highly dependent on the availability of accurate, representative, and well-labeled data. Inconsistent sensor performance, missing data, and historical biases can adversely affect model reliability.

Another challenge lies in model interpretability. Many advanced AI techniques operate as complex computational structures, making it difficult to fully explain how specific conclusions are reached. This lack of transparency can reduce trust among engineers and decision-makers, particularly in safety-critical applications.

Integration complexity also poses challenges. Implementing AI systems requires compatibility with existing infrastructure, communication networks, and operational workflows. Organizational readiness, skill gaps, and resistance to technological change can further influence the success of AI adoption in pipeline monitoring.

9. Future Directions of AI in Pipeline Monitoring

The future of AI in pipeline monitoring is closely tied to advances in computing, sensing, and digitalization. As real-time data availability increases and computational capabilities expand, AI systems will become more autonomous, accurate, and context-aware.

Emerging trends include self-learning monitoring systems that adapt without human intervention, intelligent agents capable of coordinating across pipeline networks, and digital twins that integrate AI-driven monitoring with virtual representations of pipeline assets. These developments will further enhance predictive accuracy, operational resilience, and lifecycle management.

AI is also expected to play a growing role in integrating pipeline monitoring with broader digital oil and gas ecosystems, enabling seamless interaction between subsurface, surface, and transportation systems.

10. Conclusion

Artificial Intelligence represents a paradigm shift in pipeline monitoring, transforming traditional reactive systems into intelligent, predictive, and adaptive frameworks. Through advanced data analysis, anomaly detection, predictive integrity assessment, and automated decision support, AI enhances the safety, reliability, and efficiency of pipeline operations.

While challenges related to data quality, interpretability, and integration remain, the theoretical foundations of AI-driven pipeline monitoring demonstrate clear advantages over conventional approaches. As digital transformation continues to reshape the oil and gas industry, AI will play an increasingly central role in ensuring the integrity and sustainability of pipeline infrastructure.

In purely theoretical terms, AI enables pipeline monitoring systems to move beyond observation toward understanding, anticipation, and intelligent action—marking a critical evolution in the management of energy transportation networks.

Written by Dr.Nabil Sameh

-Business Development Manager (BDM) at Nileco Company

-Certified International Petroleum Trainer

-Professor in multiple training consulting companies & academies, including Enviro Oil, ZAD Academy, and Deep Horizon , Etc.

-Lecturer at universities inside and outside Egypt

-Contributor of petroleum sector articles for Petrocraft and Petrotoday magazines, Etc.